Preparing for Your 2024 RFP? Here Are 7 Steps for a Better Transportation Bid

After two years of seismic disruption to supply chains everywhere, 2023 has brought about a much more stable environment (for shippers, at least).

But there is still a lot of uncertainty, which makes preparing for your next transportation bid — also known as a Request for Proposal (RFP) — a daunting task.

As you gear up for your next procurement event, it’s always worth your time to critically evaluate your current processes.

Setting (and sticking to) a sound transportation management strategy now will pay dividends throughout the year.

Want improved carrier performance and more predictable freight spend? Keep reading.

7 Steps for a Better RFP

- Create a Stable Operating Environment

- Establish KPIs That Define Success

- Align Procurement & Operation Goals

- Understand the Current Market State (and Where it’s Heading)

- Refine Your Carrier Strategy

- Have the People & Technology Resources to Conduct an RFP

- Overcommunicate with Internal Stakeholders & Providers

Whether you’re preparing a multi-round bid event covering thousands of lanes or just brushing up an Excel doc for a few select carriers, these best practices will help you purchase transportation more strategically:

Let’s dive into a more detail on each step so you can have a successful transportation RFP.

Step 1: Create a Stable Operating Environment

Before you can do the exciting things in your network bid, you need to do the basics well.

Though this seems obvious, many shippers who have yet to establish a foundation of operational excellence want to jump into benchmarking studies and consultative supply chain engineering.

That’s like trying to do algebra before understanding your times tables.

Establishing a stable operating environment takes a combination of technology and human expertise.

Here are a few of the basic elements every supply chain needs to have in place before looking into procurement strategy.

A stable operating environment takes a combination of technology and human expertise.

Supply Chain Technology Basics

Every shipper, regardless of size, needs a centralized way to track, store and analyze supply chain data.

Depending on your network’s complexity, that may be a simple shared Excel doc, an integrated TMS or an extension of your company’s ERP or WMS system.

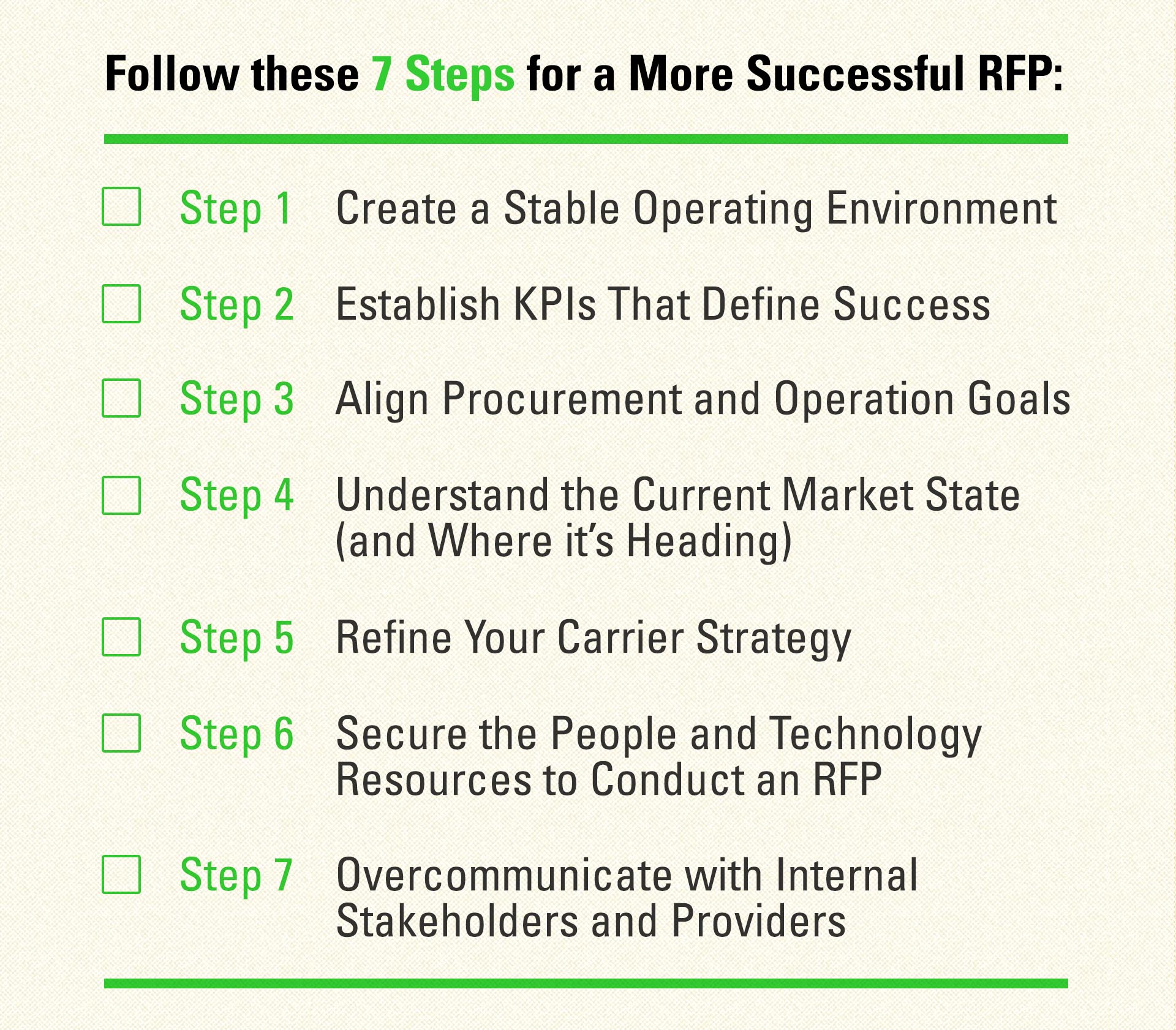

To find out what systems shippers are actually using, we asked over 850 decision makers in this original research study on supply chain automation.

Here’s what your peers are using:

- 75% of shippers have a WMS

- 72% of shippers have a TMS

- 62% of shippers use RFP management/eSourcing platform

Whatever the right solution for your business, you should be able to — at a bare minimum — do these three things in a clean, centralized way. If not, you need a better system.

- Analyze accessorial spend

- Track spend by carrier

- Evaluate performance by carrier

Human Expertise Basics

Like technology requirements, the human expertise an organization needs will vary depending on how complex its operations.

Some networks require whole teams dedicated to each facet of the supply chain, while others can rely on a few people to cover multiple aspects.

Regardless, virtually every supply chain should have people focused on the following:

- Order management

Intakes all customer orders, oversee customer service and collaborate with load planners to build shipments. - Procurement

Focuses on setting the strategy for purchasing transportation. - Load planning and tendering

These act as the conduit to carriers and 3PLs. In addition to issue resolution, they should foster and develop carrier relationships. They should also focus on network optimization, which may or may not involve procurement.

Step 2: Establish KPIs That Define Success

Having a data-driven supply chain will cut costs and improve efficiency, but figuring out which data you should pay attention to is not always simple.

There is no uniform set of supply chain key performance indicators (KPIs) — every business will track and weight KPIs differently.

Regardless of your specific situation, here’s a good rule to keep in mind: don’t start with the KPI — start with a business goal.

Once you define what you’re trying to achieve, you can work backward to decide which KPIs will actually measure success.

If you are reporting on a KPI but are not totally clear on how it ladders up to a business goal, you are probably collecting data for data’s sake (and potentially creating confusion).

A good rule to keep in mind: don’t start with the KPI — start with a business goal.

Setting KPIs for Your Transportation RFP: 2 Examples

Business Goal: Deliver orders to our customers faster.

- Most Meaningful KPI:

Total time from purchase order receipt to final delivery at customer.

This will clearly show your order fulfillment speed without including unnecessary variables. - Potentially Misleading KPIs:

On-time pickup and delivery

Just because you set an appointment doesn’t mean it was efficient. Carriers can be 100% on-time to poorly set appointments. This won’t measure what you could have scheduled for better transit times.

Cost per mile

To reach customers as quickly as possible, you may change your network to reduce overall length of haul. This would likely increase your cost per mile.

Business Goal: Prepare our network for an inflationary market.

- Most Meaningful KPI:

Your compliance to RFP awards (= # of shipments tendered to primary carrier / # of shipments you awarded)

Too low a percentage (significantly under 80%) means you are not meeting carrier expectations, giving them less incentive to accept volume surges when rates and/or demand pick up. Too high a percentage (significantly over 100%) and you could be overburdening your carrier, risking underperformance. - Potentially Misleading KPI:

Cost per mile reductions

At a time when you’re anticipating increasing rates and volatile conditions, budget cuts are not necessarily a good thing if you’re pull freight away from your most trusted providers.

Step 3: Align Procurement & Operation Goals

You have your team and processes in place.

You know what you’re measuring and have the ability to do it.

Now, it’s crucial to make sure everyone is on the same page.

The smaller your shipping organization, the easier that will be, but for larger shippers some healthy debate between procurement and ops will usually exist.

It’s a classic tale: procurement wants to cut costs and operations wants to maximize service (and their respective compensations are usually tied to it).

Usually, the best strategy lies somewhere in between: service, but not at all costs.

Your Procurement Strategy Should Match Your Corporate Strategy

- If you are a low-cost commodity provider, then your procurement strategy should reflect that.

- If you manufacture a premium product, your procurement strategy should reflect that.

- If you are somewhere in between, seek a balance understanding there will be some trade-offs.

Get Everyone in Lockstep Before the Bid

Establish a steering committee with leadership from every relevant business unit, whether by function, region, or both.

Meet routinely throughout the year, with greater frequency in the months approaching your annual procurement event. Clearly define goals based on input from across the organization.

If you can’t get in total agreement, at least everyone will be fully aware of how you’re approaching the RFP and the goals by which your organization will measure success throughout the bid cycle.

Establish a steering committee with leadership from every relevant business unit.

Step 4: Understand the Current Market State (and Where it’s Heading)

First of all, you will need:

- A solid grasp of how supply and demand work in the industry

- A complete overview of the U.S. truckload market

- The most up-to-date truckload market update and forecast.

Once you have the baseline knowledge, you can use it to guide your procurement strategy.

What to do in an inflationary market (or heading into one).

Manage up to your executive leadership team as early as possible.

Whoever is in charge of budgets will expect year-over-year cost-savings, whether or not it’s realistic. You need to start the education process sooner rather than later.

Lean on your strategic relationships.

By awarding as much freight as prudent to providers with high acceptance and service levels in periods when you don’t need them, they will be there when you do.

When freight demand outstrips available capacity, they will treat you as a premium customer.

Use spot freight as an incentive.

Many procurement and finance people might shiver at the thought, but do not automatically give spot freight to the lowest bidder.

In an inflationary market, available loads at current rates are an asset you can leverage to secure future capacity. Carriers are much more likely to give you capacity in a tight market if they have access to your spot freight.

Procurement and finance might shiver at the thought, but do not automatically give spot freight to the lowest bidder.

Step 5: Refine Your Carrier Strategy

Every shipper should have a diversified supply base.

Relying on too few carriers closes you off from opportunities and exposes you to capacity risks, but adding too many spreads your spend too thin while creating operational nightmares.

See how Pregis optimized its supply chain by reducing its provider base.

Carriers and 3PLs are like tools: they should all serve a different purpose in your network that plays to their strengths.

4 Main Categories of Service Providers You Should Use

- Strategic Partners

This is the provider that supports you through thick and thin. When you have a last-minute shipping project on July 4th, this is your first call. Engage in mutual planning that shares risk and opportunity with these providers, taking a long-term approach. - National Carriers

These carriers offer wide coverage that gives you a broad scope. Use them to fill in the gaps to establish blanket coverage. - Regional Carriers

They might not be able to cover everything for you, but their service and pricing in their areas of operation are unparalleled. Leverage them when you have an overlapping footprint. - Niche Providers

Even predominantly dry van shippers will have some non-traditional needs. These carriers can help you out when you need white-glove service to bring product up to the fourth floor, ship an oversized load across state lines or run an expedited, high-risk, high-value, power only hazmat load.

You Have Your Providers. Now What?

Once you have your mix of carriers set, try to do the following with each provider.

- Set minimum spend thresholds across all types of providers.

That amount should change based on the carrier size. - Understand how you fit into their organization.

Ask questions and find out. For example, if you do a few thousand in annual spend with a large, publicly traded national carrier, they’re going to treat you transactionally. This isn’t necessarily a bad thing, but you are far less likely to get dedicated service reps or preferential capacity. - Build relationships as high up the chain as you can.

Know their executives whenever possible.

Step 6: Have the People & Technology Resources to Conduct an RFP

You achieved alignment in your organization, you set your strategy and you understand your position in the market cycle.

Now it’s time to conduct the bid, but to do that, you’ll need to make sure you have the team and technology in place.

Here’s how your peers are running their bids:

- 31% use their TMS

- 31% use their ERP system

- 18% have a manual or homegrown process

- 11% use a 3rd-party platform

- 10% have no solution in place

Dive deeper with the full study.

Here Are 4 Other Things to Keep in Mind When Running Your Bid:

1. When you should do your RFP.

It should sync with your budgeting cycle. If at all possible, conduct your RFP first, then set your budget. Most shippers hold annual procurement events in Q4 and Q1.

2. Send a welcome letter to all providers.

Be as clear and detailed as possible by outlining what KPIs matter most to you. Tell them how many rounds they should expect. Set accurate target rates. Provide a fair accessorial schedule.

3. Don’t take too long.

From welcome letter to award, the RFP event shouldn’t take more than six to eight weeks. If it’s longer than that, you expose yourself to risk.

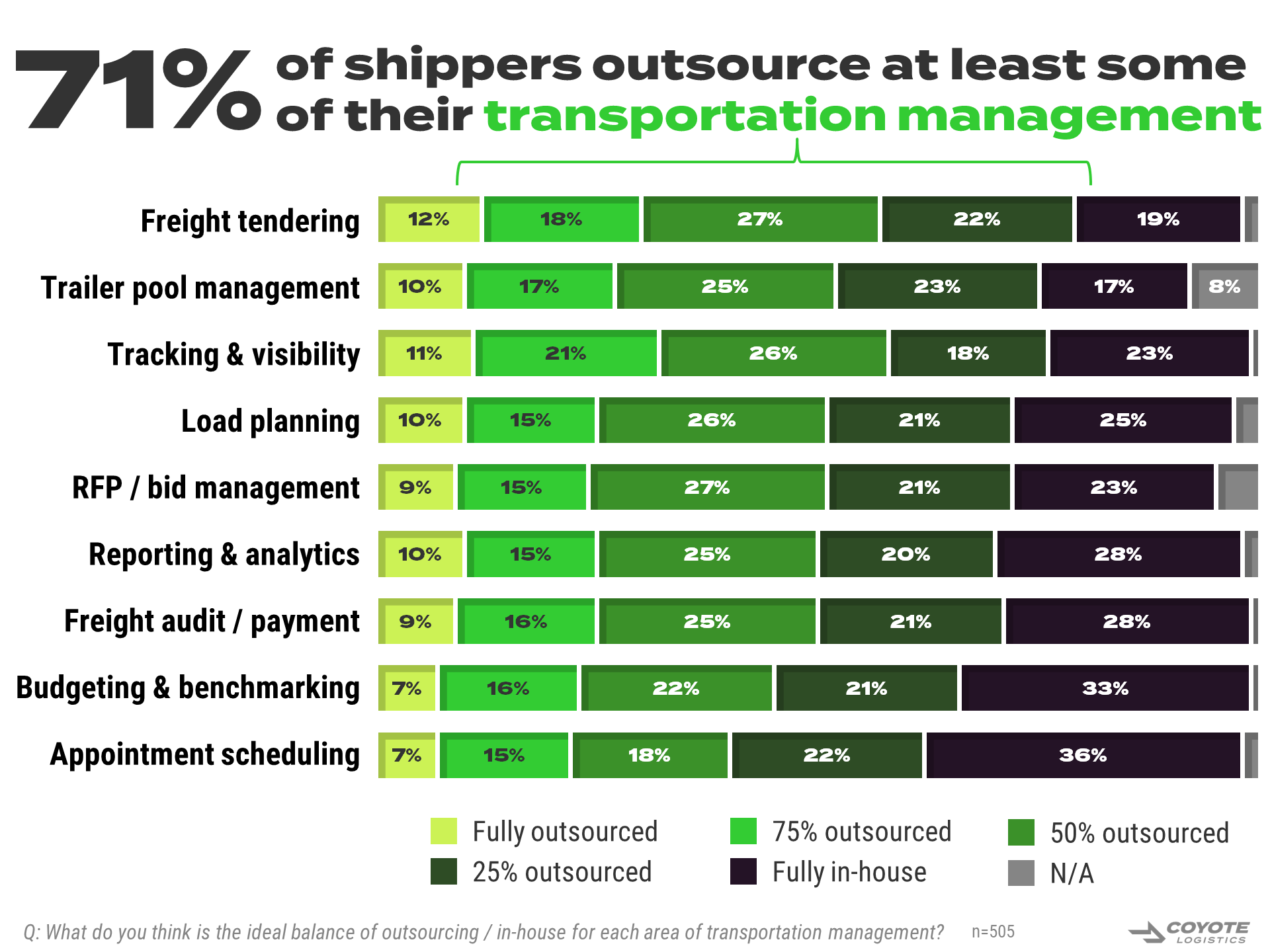

4. Consider outsourcing when applicable.

Depending on the size and complexity of your bid, you may want to consider a third-party system if your TMS (assuming you have one) cannot handle it.

According to our study on supply chain outsourcing, 72% of shippers use third-party providers for at least some of their bid management / RFP.

You will not be able to conduct advanced scenario analysis without the right tool and you will also need the right people.

If you do not have the human expertise to run complex network analysis, consider outsourcing the bid completely. The larger shippers grow, the more likely this becomes.

Step 7: Overcommunicate with Internal Stakeholders & Providers

Once you’ve communicated the awards, get definitive acknowledgment from carriers on the lanes they’ve been awarded.

Often, carriers will make bid offers based on contingencies. It is also possible something changed in their network.

Taking the time to double-check that each provider is aware of their award, understands your expectations and agrees to their rates will avoid misunderstanding (and you re-bidding some of your lanes).

Your perception of a bid award is not always the same as your carrier.

Confirm Your Awards, Then Do the Following:

- Reiterate the KPI expectations you set in step 2.

- Create a guide and have them sign it.

- Make sure you have a regular process for carrier scorecarding.

Managing Your Carriers Throughout the Bid Cycle

Carrier scorecards should be clear and simple, and you should be able to record the results from day one.

Have weekly or bi-monthly meetings with your carriers, especially at the start of the bid cycle. Though you should monitor overall performance, primarily focus on lane-level performance.

If a carrier is underperforming on a particular lane, give them an improvement deadline (two weeks is reasonable) and a consequence for continued underperformance (removal is often the case).

If they are still performing well on other lanes in your network, no need to disrupt service across the board.

RFPs are Challenging — Following These Steps Will Help Them Run Smoother

There are no shortcuts to becoming an industry leader in transportation procurement.

It takes time, consistent focus and an organization-wide commitment to a shipper-of-choice strategy — but the returns are well worth the investment.

Though your exact procurement approach will change based on the size, scope and complexity of your shipping organization, these straightforward steps will help set you up for a more successful annual procurement event.